REMANUFACTURING KNOWLEDGE AND PRACTICE

Type B4: Subcontracted remanufacturing with independent retail and reverse logistics

Also based on the type 2 model, in this case both distribution and reverse logistics operation are carried out by independant actors. These two activities can either be carried out by the same or different companies. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 4

Frequency within the survey: 5,26%

TYPES OF REMANUFACTURING NETWORKS

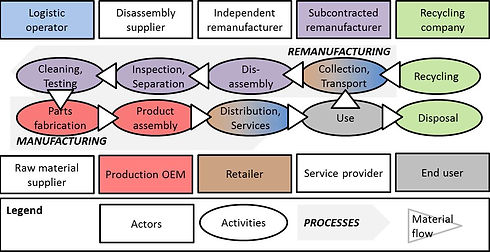

A survey, aiming at identifying the different actors within remanufacturing networks, had been carried out during the REMATEC Exhibition, held in Amsterdam from June 14th to 16th, 2013. Additionally, remanufacturing companies from Brazil brought their contribution through an online version of the survey. A total of 76 companies indicated what their partnership structure looks like. The following 11 types of networks have been identified.

Case A

Remanufacturing is integrated in OEM processes

Type A1: Full OEM remanufacturing

In this network, the OEM is in charge of all the activities within the manufacturing and remanufacturing processes. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 18

Frequency within the survey: 23,68%

Type B1: Subcontracted remanufacturing

The OEMs create a subcontracting partnership with a company specialized in the remanufacturing of its products. There is a collaboration between both actors in order to ensure efficiency of the process. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 12

Frequency within the survey: 15,79%

Type B2: Subcontracted remanufacturing with independent distribution

This model is similar to type 2, but in this case the OEM decided to focus only in the new products production and distributes his product through an external distribution company.

Number of cases observed: 8

Frequency within the survey: 10,53%

Type C1: Independent remanufacturing

In this network, the remanufacturing operations are carried out without collaboration with the OEM. It is very frequently the case of products with a high value remaining at their en-of-life phase. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 8

Frequency within the survey: 10,53%

Type A3: OEM remanufacturing with independent reverse logistics

In this case, the OEM is in charge of all the activities within the manufacturing and remanufactruinfg processes, apart from the reverse logistics. This activity is managed by a specialist, working in close collaboration with the OEM. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 3

Frequency within the survey: 3,95%

Type A2: OEM remanufacturing with retailer as distribution and reverse logistics manager

This network shows a specific extension of the role of distributor to the one of reverse logistics manager. The OEM mandates the retailer to collect the product that he is in charge of seeling after their end-of-life phase. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 10

Frequency within the survey: 13,16%

Type A4: OEM remanufacturing with different distribution and reverse logistics manager

Similar to type 7, this network shows the case of distinctive actors for the distribution and the collection phase. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 2

Frequency within the survey: 2,63%

Type B3: Subcontracted remanufacturing with independent reverse logistics

This networks shows an outsourced remanufacturing combined with an external collection of the end-of-life products. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 5

Frequency within the survey: 6,58%

Type C2: Independant remanufacturing with independent reverse logistics

As in the type 9, an independant actor is in charge of the reverse logistics. In this case, the end-of-life products are delivered to an independant remanufacturing company with no link to the OEM. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 4

Frequency within the survey: 5,26%

Type C3: Independent remanufacturing with different distribution and reverse logistics manager

In this network, the OEM is only in charge of the production of new products. The distribution of the products is outsourced and both of the reverse logistics and the remanufacturing operations are managed by independant comapnies. Recycling and diposal are treated separately by specialized companies.

Number of cases observed: 2

Frequency within the survey: 2,63%